Epoxy question

|

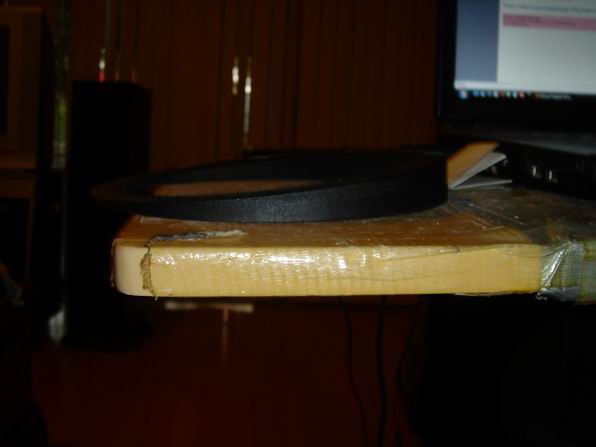

Diamond Member Username: BestmankindPost Number: 21130 Registered: Oct-05 | ok you epoxy pros answer a few questions for me. please. i read the label and it says it will bond everything. well the rings are mdf and the surface will be plastic. so i am pretty confident it will bond. question is, you think it will be strong enough to hold the speakers up? also during hot summer will the bond get loose? as you can see in the pic below, i have the 5 minute epoxy. should i get the 30 minute epoxy so i have more time to work with? should i sand the plastic surface before appying the epoxy? thanks in advance.   |

|

Gold Member Username: BernymacCambodia Post Number: 4022 Registered: Sep-04 | sand and use alcohole so there is no oils from armor all remember chad. I would also get some type of clamps to clamp them down while they are drying. |

|

Gold Member Username: Talon01Team Revolution , Pa Usa Post Number: 1341 Registered: Jun-07 | that may nor hold as there is specific epoxy for plastic i would use a rubberized ca like ic2000 |

|

Diamond Member Username: BestmankindPost Number: 21132 Registered: Oct-05 | so you are confident they will hold berny? also those rings are the angled ones |

|

Gold Member Username: Safe_crackerChicago, IL US Post Number: 4600 Registered: Jan-06 | Use the epoxy to TEMP hold the rings to the plastic. Afterwards use a mixture of fiberglass chop/polyester resin on the outer of the ring joining the plastic. I encountered this problem when modifying my Q-pods which are plastic. You need to sand the plasic well in all directions, don't just go up/down or in circles do it in all directions with a 60 grit then use rubbing alcohol and an old clean towel to wipe the area down. Polo.. |

|

Diamond Member Username: BestmankindPost Number: 21133 Registered: Oct-05 |  |

|

Diamond Member Username: BestmankindPost Number: 21134 Registered: Oct-05 | alright thanks again berny, scott and polo. i will take all your advices and attempt to make it in to one. btw polo wouldn't that look messy? |

|

Gold Member Username: BernymacCambodia Post Number: 4023 Registered: Sep-04 | http://urethanesupply.com/storeepoxy.php flex filler 2. thats the right way to do it. |

|

Gold Member Username: BernymacCambodia Post Number: 4024 Registered: Sep-04 | but that requires sanding, painting etc. |

|

Gold Member Username: Safe_crackerChicago, IL US Post Number: 4601 Registered: Jan-06 | Oh these are for the outer? Do you have a lower ring below the plastic? You know there isn't enough meat at the thinnest point on that ring to secure the speaker. polo.. |

|

Gold Member Username: Safe_crackerChicago, IL US Post Number: 4602 Registered: Jan-06 | Drill holes in the thickest parts of the ring for screws. Add a little 20min epoxy under ring use the screws to secure to lower ring (below plastic. Be sure they are countersunk, once hardened mount the speaker but don't use real long screws for the speaker. Also remember longer the epoxy takes to harden more tensile strength it had (IE- 20-30 min is stronger than 5 min) Polo.. |

|

Diamond Member Username: BestmankindPost Number: 21135 Registered: Oct-05 | yeah polo the thin part don't have enough meat. lol. that is why i want to use epoxy and not screws. i tried using screws and i split so many rings. |

|

Gold Member Username: Safe_crackerChicago, IL US Post Number: 4603 Registered: Jan-06 | Hey Chad listen up, drill holes larger in the ring that will allow the speaker hold down screws to pass through the top ring. As you bolt up the speaker it will hold the angles ring down. I did the same thing and used a clear adhesive/sealant between the thin top ring and plastic layer. I am not using the adhesive to hold it down but to keep in place and seal. Polo. |

|

Diamond Member Username: BestmankindPost Number: 21136 Registered: Oct-05 | ahhh i see what you are saying. yeah good idea. so just screw the thick part and not the thin part. also make sure the screws are flushed in. |

|

Gold Member Username: Safe_crackerChicago, IL US Post Number: 4604 Registered: Jan-06 | Here is another... Take your angle ring and find say about 4-6 wood screws that would fit comfortably within the dia of the wood ring without compromising (sp) the wood integrity (sp). Once you find the hardware find a drill bit to match the dia of the head of the screws. Drill down until you have reached say 1/2" before you go all the way through maybe a tad more. Now get a bit to match the dia of the fastener threads drill down the center all the way through the angled ring. Be sure to round it out a tad to allow the fastener to fall all the way through so not to grab the top ring when tightening. this will allow you to fasten the top ring to the lower ring and use the epoxy. Rotate the speaker so the mounting holes are in between the ring holder screws. Remember there will be no ring hold down screw at the thinnest point, only the thick areas. Hope this helps now let me back to my brew...  PolO... PolO... |

|

Diamond Member Username: BestmankindPost Number: 21137 Registered: Oct-05 | thanks polo. ima get started this weekend.   |

|

Gold Member Username: Loc_outSOCAL2 RE 15 XXX Post Number: 2185 Registered: Feb-05 | Nice car Chad |

|

Diamond Member Username: BestmankindPost Number: 21142 Registered: Oct-05 | yeah gus. my car will look like that in a month or two. i will have the side and rear lip kit too. |

|

Gold Member Username: Loc_outSOCAL2 RE 15 XXX Post Number: 2186 Registered: Feb-05 | I like it. |

|

Diamond Member Username: BestmankindPost Number: 21150 Registered: Oct-05 | me are berny are in a car club. berny is the president. |

Main Forums

Today's Posts- Home Audio Forum

- Home Video Forum

- Home Theater Forum

- Car Audio Forum

- Accessories Forum

- All Forum Topics