Has anyone seen a port like this?

|

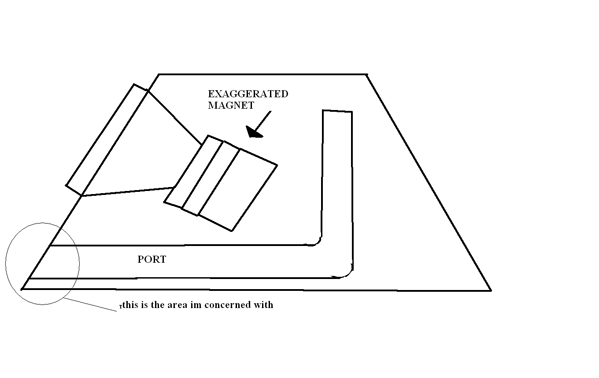

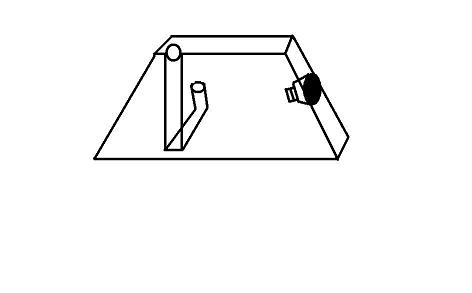

Silver Member Username: Langless28Boston, MA Post Number: 440 Registered: Dec-04 |  has anyone ever seen a port like this? cus withthe same angle as the box, would it affect airflow and tuing and stuff. and if wanted to find surface area of it, is it the same as a fustrum of a right cylinder. |

|

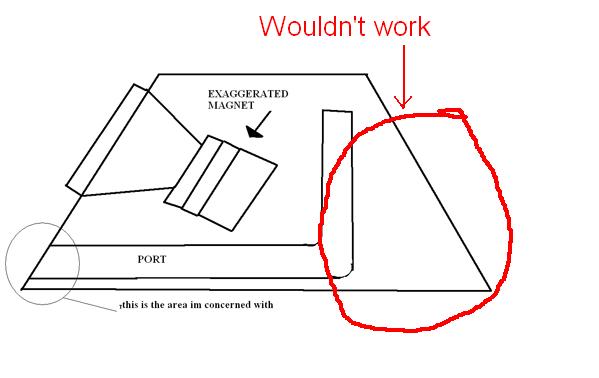

Silver Member Username: LewassBoomfield Hills, MI USA Post Number: 488 Registered: Jan-06 | That wouldn't work, the port needs to be the same exact width size and shape for the entire length of it. Also remember my diagram I did earlier, use the top port design, the angle is much freer flowing. |

|

Silver Member Username: LewassBoomfield Hills, MI USA Post Number: 489 Registered: Jan-06 |  |

|

Silver Member Username: LewassBoomfield Hills, MI USA Post Number: 490 Registered: Jan-06 | Just realized your drawing doesn't make sense, is the part labeled "PORT" the actual L shaped MDF piece, or is that the actual hollow air space of the port itself? |

|

Silver Member Username: Langless28Boston, MA Post Number: 443 Registered: Dec-04 | yeah i remember. it sucks i gotta fit a big port in a small area. lol just trying to make it work. so what would happen if the port was slanted at the end. i have a book call pocket ref and it has the equation for finding surface area of a fustrum of a cylinder. or does it involve the way the air will flow |

|

Silver Member Username: LewassBoomfield Hills, MI USA Post Number: 491 Registered: Jan-06 | As for the area you circled, I seriously doubt that having that end piece of the port angled like that will make any audible difference.. marshall? |

|

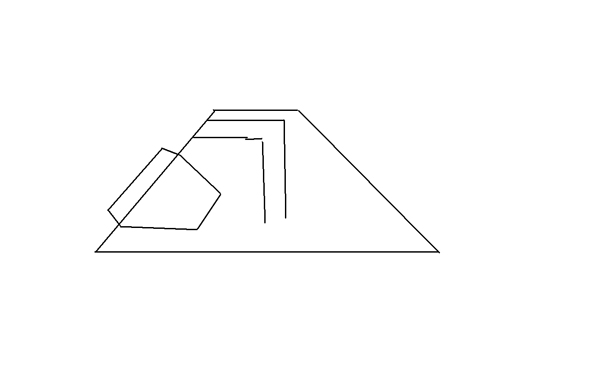

Silver Member Username: Langless28Boston, MA Post Number: 445 Registered: Dec-04 | ok, so if i did that angle thing and then a 90 degree angle up to the middle of the box would be ok? ill draw a pic |

|

Silver Member Username: Langless28Boston, MA Post Number: 446 Registered: Dec-04 | is that ok is that ok. and lewass. i member the picture, but i was drawing a slot port, this is a 4"pvc port so couldnt i be on the bottom as long as the end is 4" away from the sides? is that ok. and lewass. i member the picture, but i was drawing a slot port, this is a 4"pvc port so couldnt i be on the bottom as long as the end is 4" away from the sides? |

|

Gold Member Username: SouthernrebelMonroe, Louisiana USA Post Number: 2597 Registered: Mar-04 | you rang? yea, you can do a port like that...just try to keep it 3"-5" away from any wall (try to keep the inside mouth of the port even farther away from any wall). When you measure port length w/ a port like that, you have to measure the center-line of the port. my daily port is similar to that...my box rectangular though. http://www.cardomain.com/member_pages/show_image.pl?bg=000000&image=http://memim age.cardomain.net/member_images/2/web/650000-650999/650399_31_full.jpg http://www.cardomain.com/member_pages/show_image.pl?bg=000000&image=http://memim age.cardomain.net/member_images/2/web/650000-650999/650399_30_full.jpg |

|

Silver Member Username: Langless28Boston, MA Post Number: 447 Registered: Dec-04 | ha sorry lewass i just read your post right after my first picture, yeah slot port would be unlogical imo, so im going with 4"pvc. the part labled port is the pvc port. |

|

Silver Member Username: LewassBoomfield Hills, MI USA Post Number: 496 Registered: Jan-06 | I would try to avoid a curved PVC port, maybe do 2 ports of half the width and same total length, instead of 1 bent PVC port. (I believe that would tune the same, but I'd have to run the numbers to double check) |

|

Silver Member Username: Langless28Boston, MA Post Number: 448 Registered: Dec-04 | yeah im just afraid of port noise going to like 2" ports. why would the 90degree bend not work. i figured slot ports have 90 bends. so why not pvc? |

|

Silver Member Username: LewassBoomfield Hills, MI USA Post Number: 497 Registered: Jan-06 | Actually that wouldn't tune the same, not with cylindrical ports, only rectangular or square. What I'm trying to get at is 2 shorter ports rather than 1 bent port. Logically air should flow freer through a straight path than a 90 degree angle. |

|

Silver Member Username: Langless28Boston, MA Post Number: 449 Registered: Dec-04 | yeah, ill put the numbers into win isd. yeah two 2" ports would only be 9" long but vent mach is .09 isnt that a little on the high side? |

|

Silver Member Username: Langless28Boston, MA Post Number: 450 Registered: Dec-04 | im thinking about it, air would flow easier thru straight, so even if isd says the 4"port has low vent mach, if i add a bend but still use the same port surface area as isd says, the program wont calcualte the bend so it might actually have a higher vent mach than the two smaller ones, its just a theory, i'd like to be sure so i dont waste time and money in making a bad box. |

|

Silver Member Username: LewassBoomfield Hills, MI USA Post Number: 498 Registered: Jan-06 | Yeah, I hear ya, planning is everything when building the perfect box.. you should get marshall on this one. |

|

Silver Member Username: LewassBoomfield Hills, MI USA Post Number: 499 Registered: Jan-06 | When you think about it, air itself has almost no mass, so moving it through a bend is probably only the slightest bit harder than through a straight path.. But if you think about it, why are flared aero ports so god damn loud, I am willing to bet it's because they are straight (not to mention flared like a trumpet) and slot ports aren't as loud because they are usually L shaped... ^^^ That is mostly just intelligent speculation though, we need to hear from someone with more experience. Tried to help ya though, lol. |

|

Silver Member Username: Langless28Boston, MA Post Number: 453 Registered: Dec-04 | yeah, i have no idea what to go with, if you look at my box facing the sub, i can have that port come out hte same side as the sub and have a 90bend in it, or it can come out the right side(looking at the sub from outside the trunk, if this is the case it will be flared, but it will fire into the side of my jeep, i odnt know what to do. haha ill do some investigating |

|

Silver Member Username: Safe_crackerChicago, IL US Post Number: 651 Registered: Jan-06 | You can run ports like that, sure. Justa make sure the port is on the larger size like a 4" or you will have excessive noise around the elbo, maybe flare both ends like an Aero. Just tune it as a whole, all in the SPeaker design Cookbook, lol. Polo..  |

|

Silver Member Username: RzarectorCoquitlam, Bc Canada Post Number: 987 Registered: Dec-04 | nothing wrong with the 90.. you bend mdf slot ports 90 dont u? well sometimes anyway.. as for the angled area the end of the, im not sure the proper way to take the angled measurement on a port but id say inbetween the longest measurement of the port and the shortest measurement |

|

Gold Member Username: RovinTrinidad & T... Post Number: 6983 Registered: Jul-05 | whats the purpose of having the back board slanted ? ....... |

|

Silver Member Username: Safe_crackerChicago, IL US Post Number: 652 Registered: Jan-06 | The slant isn't enough to really affect the tuning. As long as the whole port is the same dia in/out of the elbow, there should not be a problem. To tune use the length as a whole and just measure with a tape measure, including the elbow. If you are using a high power or high excursion sub you will need a much larger dia port or more of them, JMHO..Polo.  |

|

Silver Member Username: Langless28Boston, MA Post Number: 454 Registered: Dec-04 | yeah thanks, ill be using a 12w3v2 so i think 4" is fine, as for rovin's question, im going for a stealth look, and the back of the box is the same angle as my back seats (jeep cherokee) everything fits nice and flush and looks like its meant to be there. |

|

Gold Member Username: RovinTrinidad & T... Post Number: 6986 Registered: Jul-05 | oh ok - cause it really has no acoustical advantage from what i read b4 , but now i understand ur doing it 4 looks . Thats alot more work though -lol ...... |

|

Silver Member Username: Langless28Boston, MA Post Number: 455 Registered: Dec-04 | this has been my 5th box, first was traditional ported trap, the rest have been of this kind, im mechanical engineer student so building is kinda my thing. im just stuck on what kind and where i should place the port (slanted,flared) |

|

Gold Member Username: Jonathan_fGA USA Post Number: 5871 Registered: May-04 | One thing you have to note with a ported box, you can NOT substitute two short ports for one long one. That isn't how it works, two short ports would have to be LONGER than the one to achieve the same tuning frequency. Port tuning is dependant upon the port's resistance to motion. Therefore, a longer port achieves a lower tuning frequency, while a shorter port equals a higher tuning. Similar to how a smaller or a longer length of wire has more resistance than a larger diameter or shorter length of wire. Another note, the output of a port isn't dependant upon the air it moves. A port performs like it were a solid mass, not like a hole in a box. This elaborates a bit more: http://www.hometheaterhifi.com/volume_5_2/cmilleressayporting.html |

|

Gold Member Username: Jonathan_fGA USA Post Number: 5872 Registered: May-04 | A larger port can achieve more SPL ultimately, assuming that you have to power to make it do so. But a flared port compared to a slot port of equal design, shouldn't have any difference. Main benefit of a flared port is that it prevents port noise moreso than a regular round port, or some slots. |

|

Silver Member Username: Langless28Boston, MA Post Number: 456 Registered: Dec-04 | thanks jonathan, yeah from win isd i know about using two ports and stuff, can u take a look at my first box (first post on this thread) that is a 4"dia pvc port, im wondering A, is the 90 bend gonna create resistance or mess up the tuning fq, and B, is the end of the port, (slanted with box) going to interfere with the desired tuning fq? |

|

Silver Member Username: LewassBoomfield Hills, MI USA Post Number: 505 Registered: Jan-06 | You can substitute 2 smaller ports for 1 larger one, you just have to use the proper math to calculate them... However I have read more on this since my last post, and now realize that it wouldn't be as nice a solution, because: A) a single wider port will have less port noise than 2 skinnier ports; and B) the difference between resistance of air moving through a straight path vs a curved path is so small that it's negligible. So I would go with the 4" single port, just use an elbow of the appropriate curve (that allows for the end of the port to be furthest away from the walls and the sub inside the box, while maintaining appropriate length, and an angle greater than or equal to 90 degrees) and if you really want to get it perfect, use some bondo and fill in the seams in your bend inside the port, and sand it down nice and smooth. Also, if you aren't going with the flared port opening, just use a little more filler and sand the edges to a smooth curve. You should be straight. Oh and one more suggestion, rather than making it a trapezoid, make the front face 90 degrees instead, you will get the same net volume with a little bit less depth (save a little extra trunk space, but more importantly, it'll be way easier to make the cuts if you only have 1 side slanted) |

|

Silver Member Username: LewassBoomfield Hills, MI USA Post Number: 506 Registered: Jan-06 | Oh, AND you won't have to worry about the curved port egress you circled at the top of this page... |

|

Silver Member Username: Langless28Boston, MA Post Number: 459 Registered: Dec-04 | thanks alot lewass, i had that in mind to, where the bend meets the pipe, to fill in any cracks and make it totally smooth. i hvae done this box before so cutting the wood isnt too hard, i do all my boxes out on solidworks too. its great i tell the program that i have a 2x4ft piece of mdf, and it shows what piece and where to cut them out to miminalize mdf waste. |

|

Silver Member Username: Safe_crackerChicago, IL US Post Number: 655 Registered: Jan-06 | If you make the length you you need the cap one end, fill it with dry sand then cap the other end. Gently heat where you want the bend to be it should bend without kinks, just a thought, Polo..  |

|

Silver Member Username: LewassBoomfield Hills, MI USA Post Number: 526 Registered: Jan-06 | That wouldn't gaurantee a perfect equal radius throughout the pipe though, just buy a 90 degree mandrel elbow pvc piece. It will sound just as loud whether you fill in the cracks or not, but those seams are port noise culprits.. |

|

Silver Member Username: Langless28Boston, MA Post Number: 464 Registered: Dec-04 | that might sound like it will work polo, i have ten feet of 4" pvc so ill try both methods, but yeah it would have to be a perfect heated bend, so the radius is the same. |

|

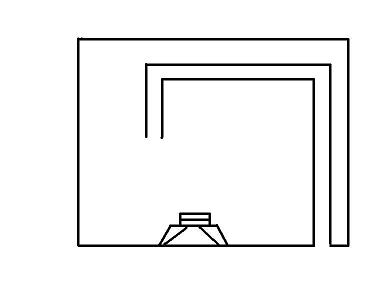

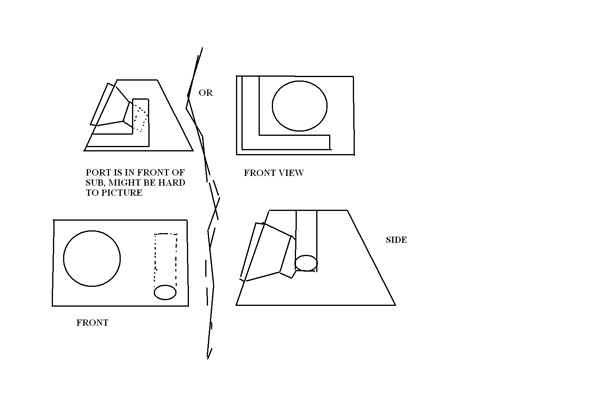

Silver Member Username: MixneffectOrangevale, Ca. USA Post Number: 872 Registered: Apr-05 | Entertain this idea; Instead of making the port go upwards, how bout making it go sideways. This will allow you more room, sure you will have more bends, but it will give you the option. Here is a "TOP" view, (not side view).  |

|

Silver Member Username: Langless28Boston, MA Post Number: 466 Registered: Dec-04 | yeah ill experiment with solid works to find what works best. |

|

Silver Member Username: MixneffectOrangevale, Ca. USA Post Number: 873 Registered: Apr-05 | Heres another idea, keeping it square on the top baffle. It would allow you to keep the port end square so that your calculations would still be precise. Please excuse the poor paint experience, but I hope this may help.  |

|

Silver Member Username: Langless28Boston, MA Post Number: 467 Registered: Dec-04 | yeah mix that was my original idea, and the box would be long enough so it wouldnt need the sencond bend, i was just thinking it would be cool to see an angled port on the front side. whichever is more convinent, im going to use. |

|

Silver Member Username: Langless28Boston, MA Post Number: 468 Registered: Dec-04 |  i absolutly hate paint. im gonna try to sketch it out on autocad (again) and jpg-out the image, so you can see it alot clearer. |

|

Silver Member Username: MixneffectOrangevale, Ca. USA Post Number: 874 Registered: Apr-05 | Personally I would take the one on the left. I like to keep the port at least 3" away from any walls or other obstacles and definetly keep it away from the driver. It sounds best when the port is away from the driver because it allows the air to bounce off of the walls before it comes out, otherwise you get port noise. |

Main Forums

Today's Posts- Home Audio Forum

- Home Video Forum

- Home Theater Forum

- Car Audio Forum

- Accessories Forum

- All Forum Topics