Note from the editor: Please welcome John Sciacca, a custom installer from Myrtle Beach, SC. For 21 years, John has written the “Connected Life” column for Sound and Vision magazine. In it, John has offered professional advice for the CI community, DIY audiophiles and home theater hobbyists. We’re pleased to have John join us here at eCoustics to carry on this tradition. John’s experience with all manner of custom installation of audio, video and smart home systems makes him a great resource to those hoping to go beyond the basics of audio and video system building. Got a question for John? Let us know in the comments or via e-mail at feedback@ecoustics.com.

Table of contents

The Basics

Greetings, eCoustics readers! I was all prepared to write my first post about in-ceiling speakers, where I would address multiple questions such as:

- Are in-ceiling speakers good for Dolby Atmos height channels? Yes!

- Can a ceiling fan affect the performance of in-ceiling speakers? Also Yes!

- Are in-ceiling speakers hard to install? It depends…

As I started going through the list of questions, I realized that anyone likely asking these questions doesn’t already have in-ceiling speakers installed, and before you even get to the part where we can talk about the pros and cons of in-ceiling speakers, we need to address what it will take to make that happen in a home.

As to the “Why?” well that’s pretty simple. More and more movies and TV shows, and even music titles, are being released in Dolby Atmos immersive surround. This enhances traditional surround sound by adding a third dimension: height. Now sounds can come from not just all around you but above you as well. And, while reflective Dolby Atmos speakers that bounce sound off the ceiling can work reasonably well in some rooms, nothing compares to direct sound coming from above the listener for a truly immersive and exciting viewing and listening experience.

And, spoiler alert, depending on your home, when and how it was built, where your electronics are located, and the room(s) you want to install these speakers, installing in-ceiling speakers may not be possible, or may present challenges that are difficult to overcome. But hey, you can always call an installer if it gets overwhelming. In most cases, it’s entirely doable once you understand what’s entailed.

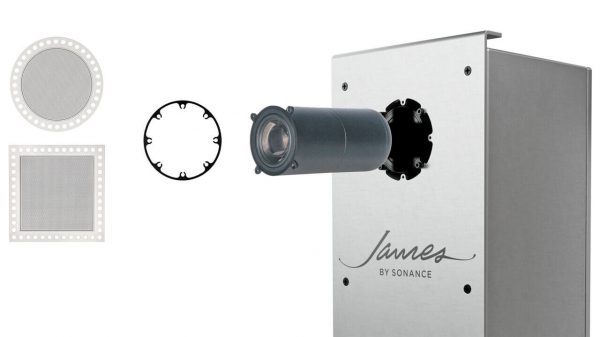

For the sake of this article, in-ceiling speakers typically refer to round, whereas in-wall speakers generally refer to rectangular shaped speakers. However, in almost all cases, you could put a round speaker in a wall and a rectangular speaker in the ceiling. The mounting brackets might vary, but the choice is really up to the owner and the difference is usually one of aesthetics.

Start With Wiring

So, the actual installation of the speakers themselves is pretty simple and straightforward, and requires little more than using the included template, a pencil, a drywall saw, and a cordless drill. But, we’ll cover the particulars of that in a later section.

The trick of the install is getting the wire from your electronics to the speakers.

And, despite all the advancements in wireless technology, every in-ceiling speaker that I’m aware of needs some sort of wiring. And in 99.9% of cases, this is traditional 2-conductor speaker cable, with a few specialty speakers getting their signal via PoE++ (Power over Ethernet) and using Category rated data cabling instead of speaker wire. Even so-called “wireless” speakers need power so there’s that pesky wire requirement again.

For most speaker runs, 16-gauge speaker wire is fine, with 14-gauge being better for longer runs, and 12-gauge being better still. The lower the gauge, the thicker the cable. Thicker speaker cable offers lower resistance, allowing less signal loss over longer distances as well as less heat build-up. But with the low voltages in a speaker signal, heat isn’t normally a problem, even in higher gauge cables.

Because the wire is going to be running inside your walls, you’ll want to use wire that has a CL2 or CL3-rated jacket that is fire-resistant and meant for low voltage applications.

Wiring Challenges

To better understand the challenges you’ll be facing with an installation, I created a drawing of what a typical wall looks like in modern homes if you tore off the sheetrock. The diagram assumes a single story home but the concept applies to multi-story homes as well.

This is essentially what we are working with during new construction or a major remodel of an existing home. The walls are all open and exposed down to the studs, and pretty much anything is possible. This is why it is so important to get the wiring done during construction if at all possible, before the drywall goes up. (Actually, it’s preferable to do it before the insulation is installed as well, as it’s just a horrible itchy mess to work in). But DIYers may not be as eager to completely remove the outer walls. Don’t despair – there is hope!

Find the Studs

Walls are typically framed using 2 x 4 studs – which actually aren’t 2-inches by 4-inches, but rather are 1.5 x 3.5-inches – and they are typically 8-feet long. These studs are generally placed 16-inches on center, which means the center of one stud to the center of the next stud measures 16-inches. This leaves a gap between the studs of 14.5-inches.

Because the studs are 8-feet long, if your wall height is greater than 8-feet tall, then you’ll have more framing where these studs are joined together. Also, depending on local building code – and when your home was built – you might have purlins (or fire blocks) placed horizontally between studs. Purlins, which could be made of metal or wood, not only reduce the spread of fire, but provide additional structural rigidity and support in both walls and roof supports. Where I work in South Carolina, all exterior walls are required to have these post Hurricane Hugo, and many builders install them in interior walls as well.

It’s important to understand that these purlins may exist as these internal obstructions could stop you from being able to run wires inside your wall all the way from the bottom to the top of the wall using fish tape, a fiberglass wire running rod or similar tools.

You’ll also notice that the wall boxes are attached/nailed into a stud. This is useful because these big blocks of metal can help you to locate the studs in your wall, and then once you’ve located one stud, you can measure and determine where other studs are. You can also use a stud finder (which can be finicky) or (and this is a total #ProTip) use a powerful rare earth magnet which will locate the screws the drywall installers used to attach the drywall like a StudPoP Smart Magnetic Stud Finder ($11 at Amazon).

Going Into the Attic

So, imagine that your electronics (specifically your surround receiver) are sitting in a cabinet on the floor. Unless you want to run surface-run wiring outside the wall or ceiling and up the wall in a conduit or raceway (yuck!), you’re going to need to go into the wall, up the wall, into the attic, and over to where you want the speakers located before you can worry about installing the speakers themselves.

“But, John, my house doesn’t have an attic, or I want to install the speakers in multi-story house and there is a room above where I want them to go?”

Sadly, in this type of situation, you’re likely out of luck. There are some advanced retrofitting techniques you might be able to do (removing crown molding, pulling out recessed light fixtures, cutting access holes in drywall which are then repaired, etc.), but at that point, unless you’ve got some pretty decent construction chops, you’re probably best bringing in a custom installer for a consultation.

How to Run Speaker Wire Inside Your Walls and Ceiling

Now let’s go over how to get speaker wire from your equipment into your ceiling. The same concepts and techniques apply to installing in-wall speakers as well.

This procedure can be a little tricky, and can require some specialty tools, but trust me: it’s totally doable and the satisfaction that comes from the first time you hear a jet fly overhead from those in-ceiling speakers is immensely worth it!

Also, while not totally necessary, we almost always do retros (adding wire to existing construction) with two people: one guy on the ground, and one guy in the attic. It just makes things go so much faster when you don’t have to keep going back-and-forth. So, if you can grab a partner to assist, your life will be simpler and the job will go faster.

Step 1: Get the Right Tools

I’ll show pictures below for context, but before you begin, you’ll need to get some tools. These include a drywall saw, an open-back low-voltage retro ring, a fiberglass wire running rod, a cordless drill, a long (at least 12-inch) drill bit that is at least ½-inch in diameter, a tape measure, a ball-and-chain wire retrieval kit, a bullet level, a pencil, some electrical tape, a drop cloth, a vacuum, and enough speaker wire to get the job done.

When I’m working on a wiring job, we’re always pulling the cable out of big boxes that have hundreds of feet of wire, so there’s no worry about running out. But, if you’re running just a few speakers and don’t want to end up with a ton of extra wire, you might call a local install company and ask if you can borrow a spool and just pay for what you use. Most wire spools are foot marked, and they can sell you the spool, and then when you return it, just charge you for the footage you used.

Step 2: Check the Wall

The wall where your audio/video equipment is located will likely have some wall plates already installed. These can be electrical outlets or maybe old cable or phone outlets. Remove the single screw and the wall plate, and then you should see something that looks like this:

(Imagine there is drywall surrounding that box). Now, unless you flipped the breaker (not necessary, but also not a terrible idea), this will be a hot box, which means that if you reach into it and touch the live wires, it will zap you. Not enough to hurt you, but enough to let you know you don’t want to do it again, so keep your fingers out of the box. Or, go turn the breaker off. As you can see, one side of the wall box is nailed to the stud, but on the other side, you should be able to bend the plastic or metal of the wall box enough to slide in the tip of your flexible fiberglass rod.

We use rods from Labor Saving Devices (who goes by the unfortunate acronym LSD) which they call Creep-Zit (seriously, who names these things?). These rods are about 6-feet in length and you can screw them together to extend them if need be. Slide one of these rods in between the edge of the wall box and the sheetrock and push it up inside the wall as far as you can. In a perfect world, this will go all the way up to the top plate and your install will be pretty straight forward.

However, if you hit something like a purlin or fire block, you’re not out of luck, but you’re going to have a tougher go

Step 3: Drill Down from the Attic

Before heading up into the attic, use some electrical tape and tape on a couple of feet of ball chain to the end of a flex-rod.

Using the flexible, magnetic “wet noodle” ($30 at Amazon) (again with the weird names!) is going to make it easier to retrieve the wire inside the wall later. Then, grab a flashlight, your cordless drill, the flex-rod with ball chain, and your long ½-inch drill bit and head up into the attic.

Once you’re in the attic, it can be a little tricky to get your bearings and figure out where you want to drill down. If the electrical cable from the existing wall box comes up into the attic, that’s a great help. However, you might have to take some measurements on the ground in order to find out the right spot.

Once you’ve located where you want to be, drill in the center of the top plate straight down. At most, you should only have about three 2 x 4’s to go through which is about 4.5-inches. So if you drill more than that, you’ve likely hit a header which is another problem that probably would put an end to our install. You could try moving over a foot or so and trying again just to confirm, but if you’re into a header, this wall just won’t work. However, that’s unlikely, so we’ll press on.

So, now we’ve got a nice hole going down into the wall. Drop the flex-rod with the ball chain down into the wall. Again, we’re hoping that it will drop all the way down, in which case we’re golden. However, if it doesn’t, then we’ve got to do a bit of math.

That math is, how far up did the rod go from the ground, and how from down did the rod go from the top. That will tell us how much blocking is in the wall. Ideally there will only be one block. (Well, ideally there would be none, but that ship has sailed…)

Step 4: Cut in a Wall Box

Whether we found blocking or not – which we’ll address in a second – we’re going to need to cut in a wall box. For this you’ll need a drywall saw ($18 at Amazon), a bullet level ($8 at Amazon), and a pencil.

Using the level and pencil, trace out the hole you need to cut in for the wall box. Before cutting, put a drop cloth on the floor to catch the drywall dust, and then cut out the box.

At this point, if you didn’t hit any blocking, you might just see the flex rod in the wall. If not, you can use the flexible magnet from your ball and chain kit and move it around inside the wall till you feel it hit and attach to the ball chain and then pull the chain out. If you have two people, the guy in the attic can move the flex rod around to help with this.

Once you’ve got the ball chain out of the wall, attach the speaker wire to it with some electrical tape, and then you can pull the wire up into the attic. Hooray!

Step 5: You Hit Blocking… Now What?

Let’s assume we have only one piece of blocking to work with. We’re going to need to go through this obstacle, and to do that, we’ve got two decisions: Use a long flex-bit ($34 at Amazon) and drill it, or cut in a wall box above or below the blocking and drill it.

Option 1: Drill It

Find out which the blocking is closer to; the bottom box going up, or the top where you drilled the new hole going down. To drill this we’re going to need another specialty tool called a flex-bit.

This is a long, usually 54-inch bit that is kind of flexible that will allow us to go inside the wall and drill out that blocking. The concern is that sometimes these bits can “walk,” and you might end up going off the blocking and drilling out through the wall causing more damage. So, attach this bit to your drill and drill slowly through the blocking. It’s a good idea to have someone watching the sheetrock on either side of where you’re drilling so they can yell “STOP!” if they see you are starting to come through.

Once you’re through the blocking, go back up into the attic with a flex rod and some ball chain and you’ll have to poke around until you get that rod to drop through the hole you just drilled. Once you’ve done that, grab the ball chain from down below, attach the speaker wire to it with some electrical tape, and pull the wire up into the attic.

Option 2: Cut-In a Wall Box

This is safer option in that you’re not going to accidentally drill through the wall, but it will leave you with a new hole in your wall that you’ll either need to repair or cover with a blank wall plate. (Or, if you’re lucky, you could cut in the box behind a picture or wall-mounted TV so you’ll never see it!)

Measure to where you will be either just above or just below the blocking, and then use the same technique in Step 4 above to cut in a wall box. Once you cut in the box, you’ll see the blocking, and then you can use your drill to make a nice hole through it for the wire to pass through. Once done, use a flex-rod to get from the bottom wall box all the way up into the attic, attach your speaker wire to it with some electrical tape, and pull the wire up into the attic. Be sure to pull through enough wire runs to connect all of your in-ceiling speakers and leave extra cable in the attic until you’ve measured out the exact speaker placements.

Step 6: Install the Wall Box

Once you’ve got the speaker wire up into the attic and landed to where your speakers will install, you’ll want to finish out the wall box you cut in originally. This is where your A/V receiver or amplifiers will connect to those cables you just installed into your wall. For this you’ll want an open back existing construction wall box ($7 at Amazon), and a speaker wiring plate ($14 at Amazon). Be sure that your wiring plate supports as many speaker connections as you need.

Install the wall box and make sure it is nice and level, and then attach the speaker cables to the back of the wiring wall plate and screw the plate into the wall box. Use your vacuum to clean up any extra drywall dust.

Tip: Instead of using speaker wall plates, a brush plate ($7 at Amazon) allows a bundle of speakers wires to flow out from the wall and directly into an amplifier or A/V Receiver. Either way remember to label each wire (and wall plate) so you’ll know exactly where each wire is going.

Congratulations! You now have speaker wiring running inside your wall from your electronics components to your new speaker locations in the attic.

How to Install In-Ceiling Speakers

With wiring completed, let’s get those in-ceiling speakers out of the box and into your ceiling. We’re going to assume that you’re installing four height speakers as that’s generally the ideal number for a medium to large home theater or living room, but the concepts are the same if you choose to only install two ceiling speakers or even go with six or more. OK, Here we go!

Step 1: Measure Where They are Going

Remember the old adage “measure twice, cut once”? That will be our mantra here. Before you get to cutting, make real sure you’re in the right spot. We didn’t come all this way to put a hole in the wrong place.

Of course, the best place to start when it comes to determining where you’re going to install your new speakers is by looking at Dolby’s recommended speaker layout.

As you see, Dolby’s guideline is that the ceiling height speakers are in line with the main front left/right speakers, then spaced roughly 45-degrees ahead and behind the primary listening position. If you can achieve these locations in your room, great!

But another consideration besides being properly located for sound, is that you want the speakers to look like they belong in the ceiling as well. We will often try to line them up with, or space them off things that are already in the ceiling like recessed light cans, HVAC registers, chandeliers, etc. so it doesn’t look like they were just haphazardly placed.

After determining your location, you can use a tape measure on its own, or go high tech and throw in a laser level ($40 at Amazon).

No question, the laser level makes it far easier, giving you a nice straight line you can put over the exact center of where you want the speaker to go. This is especially true if you have high ceilings, or a long room where getting a good measurement can be tricky. With or without the laser, you’ll need to measure your location off the front wall to make sure you’re putting the speakers at the same distance. Once you’ve got your measurement, use a pencil and make marks where you want the center of each speaker to go.

Step 2: Tape Up the Template

Every architectural in-wall or ceiling speaker I’ve ever installed comes with a cutout template that looks something like this:

Some companies even go the extra mile by putting some adhesive on the back of the template so you can easily stick it onto the ceiling, otherwise you can double up some painter’s tape and then put the center of that template right on your mark.

Now, nothing is more disheartening than getting to this point and then starting to cut out the speaker and feeling the drywall saw hit wood. (Shudder!) Let’s not sacrifice structural integrity for the sake of good sound, OK? So, before we start tracing or cutting, we need to make sure that we’re clear up in the attic. This might be something you can eyeball, for instance, knowing how your ceiling trussing is framed, or something you can measure, say by taking a measurement from something nearby in the ceiling and then going and remeasuring in the attic.

But if you can’t confidently determine where the speaker is going to cut in, another option is to use a probe bit ($10 at Amazon).

This 1/8-inch bit makes a tiny hole in your ceiling so – heaven forbid! – if you find out the placement won’t work, you can pretty easily cover the hole with a bit of caulk or spackling and paint. So, drill a hole through the center of your template, release the bit from the drill but leave it inside the hole. Then go up into the attic and find that bit. Or ask your attic helper to find it. Do you have clear space all around the bit? Great! If not, you’ll need to adjust the location a bit. But remember, moving the location of one speaker likely means moving the location of at least one other, and maybe all so they’re lined up and symmetrically placed. I’d recommend doing this drill bit trick with all 4 potential placements first, before you start cutting any holes. As they say, “an ounce of prevention…” This way you won’t end up with perfect placement (and huge holes) for three speakers and find out the last one is right on a beam.

If you have blown-in insulation in your attic, now is a great time to clear out a large section around where you’ll be cutting out the speaker holes. This will prevent a big mess later.

Once you’re sure that you’re going to be clear of any framing – remember, measure twice (or more!) and cut once – take a pencil and trace around the outer edge of all the speaker templates and then remove them.

Step 3: Cut Out the Holes

Sheetrock cutting is messy – especially when done on the ceiling – so lay down a drop cloth before you start. If you have a wood ceiling, you’ll need to use something like a Dremel tool or oscillating saw that can cut through wood.

In most cases you should be able to just use your drywall saw and carefully cut around your traced line.

You’ve got a little margin for error if you go a bit large (outside your trace), but usually not a lot if you go small (inside your trace). The speaker’s grill usually has a lip that will hide any small gaps. If you’ve never cut out drywall before, it can be tough to get that initial penetration of the blade all the way through. One easy way to get started is to drill a hole at the edge of your tracing large enough for you to get the drywall saw blade into the ceiling. Wearing glasses or goggles is also a nice way to keep the fine dust out of your eyes and a mask will keep that dust out of your lungs.

Now, let’s say that you are replacing an existing speaker and you need to make a larger hole? Say you’re upgrading from a 6-inch to an 8-inch woofer and need to make the hole about an inch or so bigger in all directions. Because you’re dealing with a more fragile cut due to the existing hole, you can crack the drywall and end up with a real mess if you aren’t careful. In these cases I like to pre-score the new cut out with a box cutter, which has a blade that is much sharper and thinner than the drywall saw. Basically, I’ll just go around and around cutting as deep as I can with the box cutter’s blade so the drywall saw doesn’t have as much work to do.

Step 4: Prepare the Speaker Wires

At this point you’ve got a pretty large hole in your ceiling, and hopefully you can just reach up into the attic and grab your speaker wiring. Now ideally there is enough wire here that you can pull the wire down to at least the top of your ladder, which will make it easier to connect to your speaker.

Using your wire stripper, strip back about ½-inch of insulation from the wire. Depending on your speaker, you’ll usually either have spring clips or push terminals for attaching the speaker wiring.

With the Creator Series, Monitor Audio developed something pretty cool called Quick-Link speaker connectors. With these, you remove the speaker connection terminals from the speaker, make your connections, and then the terminal magnetically snaps back and locks into place. While this sounds like a simple thing, it is surprisingly handy and definitely speeds up the installation process.

Before connecting the wire, I like to use my drill to get the dogleg mounting screws on the speakers started and make sure they are going to turn easily and then snap down correctly into place.

Step 5: Install the Speakers

Once the speaker wiring is connected, you’re ready to install the speaker. After feeding any extra speaker wire back up into the attic, slip the speaker into the hole. Provided you didn’t undercut it, the speaker should slip in pretty snugly and sit flush against your ceiling.

For the vast majority of speakers, installation is easiest using a drill with a Philips Head bit on it to screw down the four doglegs. To insure that you don’t overtighten the doglegs – which can damage the speaker or your drywall – use the clutch setting on your drill and dial it back to a setting of around 5.

I like to go around to each leg until my drill starts clicking, then once I’ve done each one, I like to finish by hand tightening each dogleg with a hand-held screwdriver.

There are a few other ways that manufacturers use to install their speakers.

Several speaker companies, such as Russound and Episode, use a feature developed by Swarm technology called Push Lock, which is a push button that releases a tensioned spring that snaps the dogleg into place. These are super handy for installation, but I find they can be a bit more difficult to undo if I ever need to get the speaker back out of the ceiling.

By far my favorite speaker install method is the Zip Clip developed by Origin Acoustics for its Director Series. (Bowers and Wilkins uses something similar which it calls QuickDogs.) This is a toolless installation method where you install a bracket in the ceiling and secure it by squeezing two clamps down that lock in using a one-way mechanism similar to a zip tie. Then, once the bracket is securely in place, you slide the speaker into the bracket and give it a turn to lock it into place. A light bracket is much easier to install into the ceiling than a heavy speaker.

While there’s nothing wrong with traditional screw down doglegs – and they certainly work – when you’re standing on the top of a ladder, balancing the speaker in one hand, trying to connect the wire with the other, and then grabbing down for your drill, and then holding the speaker up against the ceiling with the other, you appreciate any help you can get. What looks simple standing down on the ground gets harder when you’re potentially 10 feet in the air. And while I wouldn’t choose a speaker based on the mounting method alone, I also wouldn’t mind if more companies adopted things like this to make life easier for installers and DIYers.

Option 1: Tweak the Settings

Before you snap the magnetic grille into place, there might be some settings or adjustments available on the speaker itself to optimize the sound.

Depending on the speaker, you might have high, mid, and low frequency gains or cuts, or boundary gain adjustments for if the speaker is placed in a corner. Usually these are little dip switches located on the front of the speaker. Typically, I don’t mess with these when I’m doing a home theater installation, as I’ll let any room correction listen to the speaker in its neutral setting, however for whole-house audio (say if speakers are going in a bedroom or bathroom) I might make some tweaks and then listen to how it sounds.

Option 2: Aim the Tweeter

Again, depending on the speaker, you might be able to adjust the position of the tweeter and this is something that I do like to do. Even though in-ceiling speakers have pretty wide dispersion patterns, aiming the tweeter toward the listening area certainly helps focus the sound a bit, and I like to direct the tweeter toward the primary listening position where possible.

Step 6: Connect to A/V Receiver

Now you want to connect the wiring between your A/V receiver or amplifier and the speaker wire wall plate installed into your wall earlier. I always prefer to use banana plugs on both ends of these wires, as they make for a nice tight connection and make things easier if you ever need to disconnect and reconnect them. You also want to make sure you connect each speaker wire to the correct speaker output of your AVR. It may be helpful to use masking tape and a pen to mark which speaker connection is which on the speaker mounting plate (e.g., FR, FL, RR, RL). And if you want to make it easier for future installers, use a Dymo label maker – or a Sharpie – for something a bit more permanent.

In most cases, the front height speakers will connect to the Height 1 terminals on the receiver, and the rear height speakers will connect to the Height 2 terminals, but sometimes these are assignable/configurable so consult your AVR’s owner’s manual to be sure. You will also need to go into the AVR’s speaker settings menu and tell it that you now have front and rear height channels in your system. This is usually identified as a “speaker configuration” menu.

Step 7: Calibrate Channel Levels/Room EQ

The last step is to finish configuring the new speaker settings in your receiver, such as setting crossover levels (usually 80Hz), distance, and channel level. You can either do that manually, or you can re-run whatever flavor of Room EQ or calibration that your AVR supports such as Audyssey or Dirac. Even when running Room EQ, I often like to bump the levels of the height channels by 2-3 dB as I find this makes the height effects slightly more prominent. Obviously, adjust this to your own preference, but in my experience, most people that have just gone through the trouble of installing height speakers want to make sure they can hear them, and the little bump can make a nice difference.

That’s it! Now you’re ready to sit back and enjoy! Pop in your favorite Dolby Atmos movie or music track and give it a listen! And pour yourself a drink. You’ve earned it!

Related Reading: